The deciding factor between digital and offset printing is usually cost, and your printer will steer you towards the best choice for your project. But that isn’t the only factor—both methods have their limitations and each requires certain design considerations.

How they work

Offset Printing

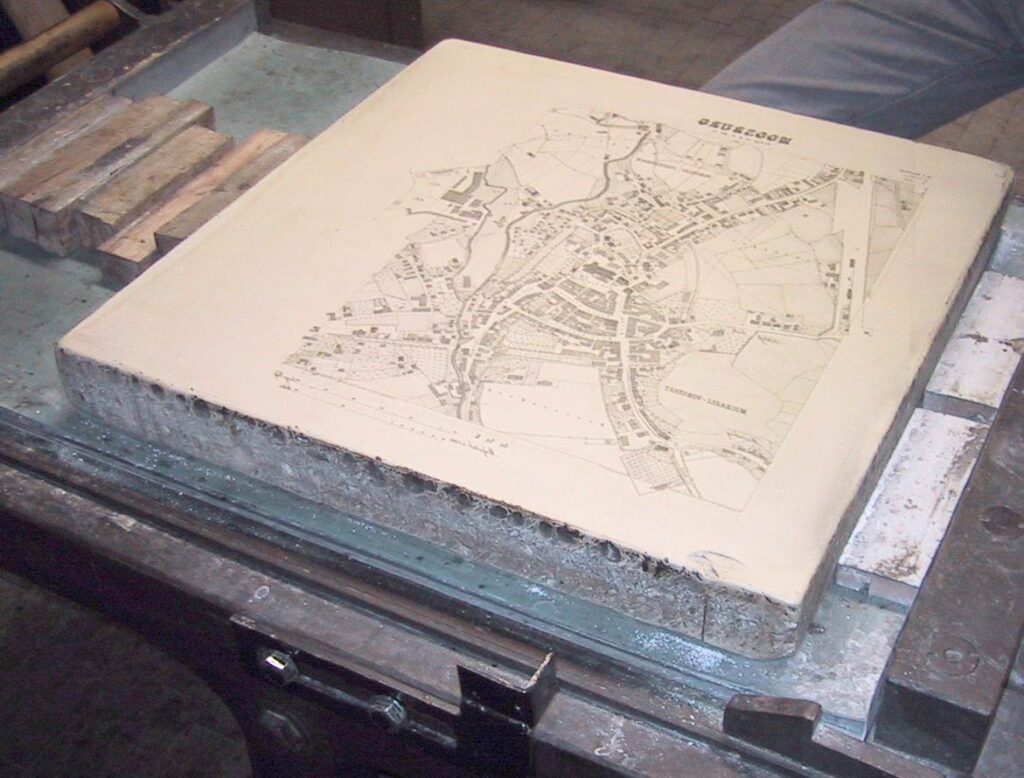

Offset printing (or offset lithography) was invented in the late 1800s and gained prominence in the 1950s. It evolved from conventional lithography (from Greek roots literally meaning “stone writing”) which used an etched image on limestone to transfer ink to paper. Lithography revolves around the principle that oil and water don’t mix.

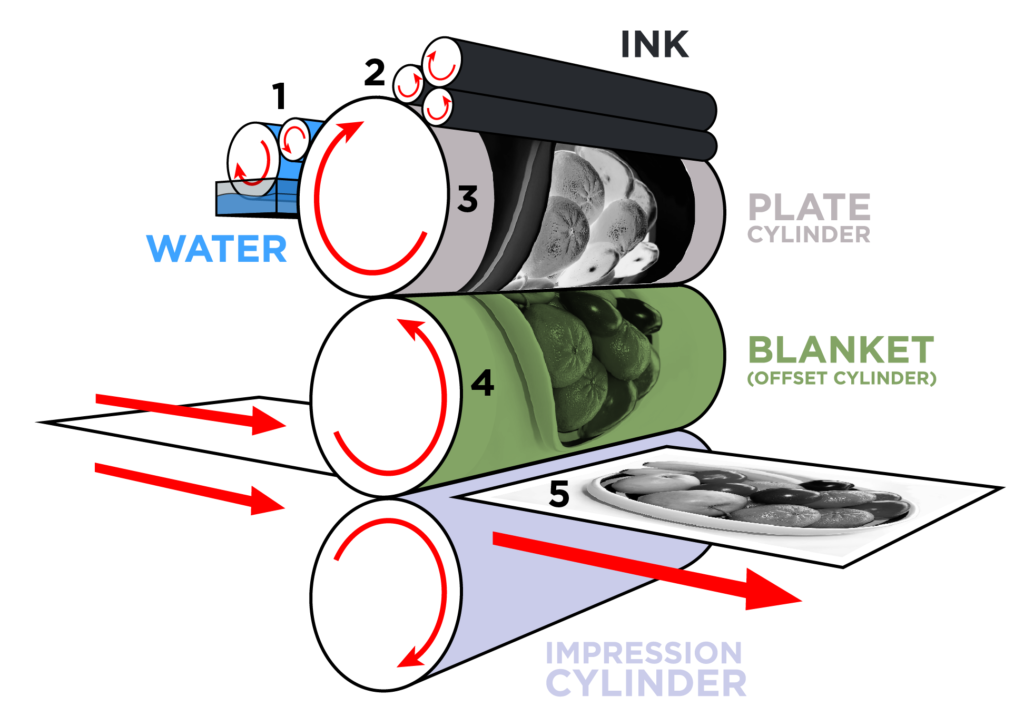

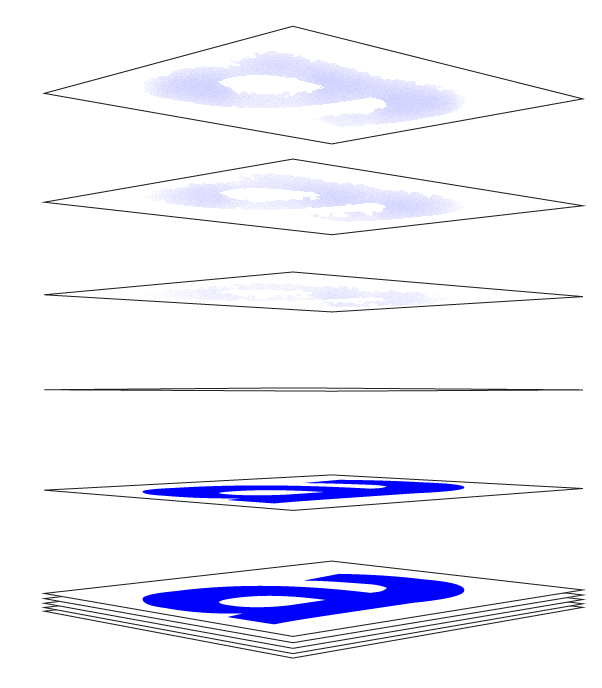

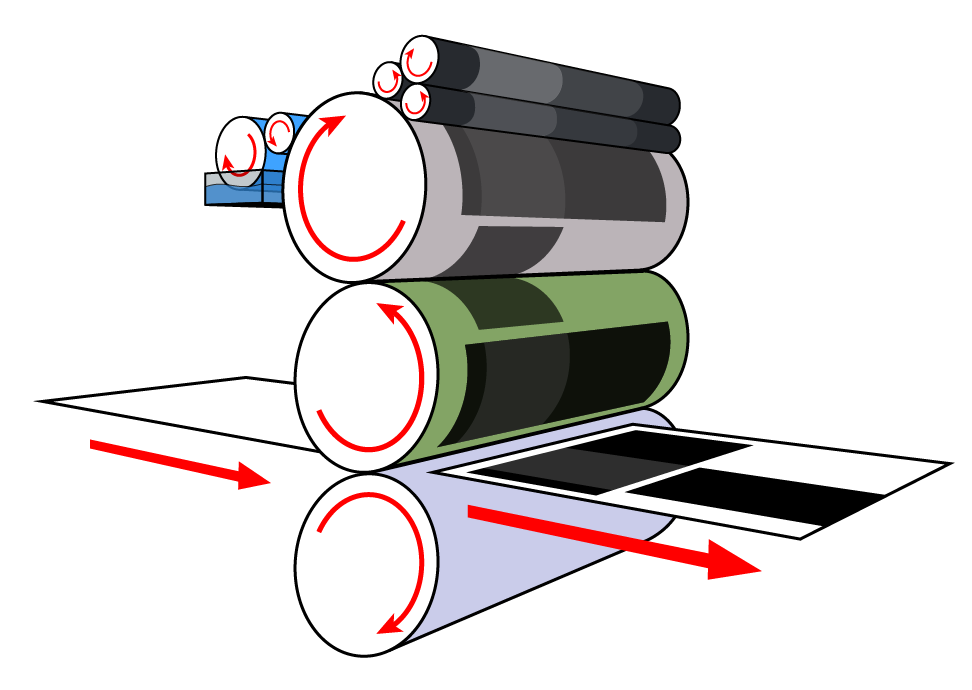

Instead of etched limestone, modern offset presses use plates made of thin metal or plastic coated with a photosensitive emulsion—the emulsion gets exposed to light and developed like a photograph. Exposed areas repel water and attract ink. The rest of the plate attracts water and repels ink. The plate is wrapped around a roller in the press, where a thin layer of water is applied, followed by a thin layer of oil-based ink. The plate rolls the image onto a rubber blanket, which wicks up the water and transfers the image on to paper. The oil base used to be derived from petroleum; these days it’s mostly soy.

Offset printing requires a skilled technician to set up. Each color needs a separate plate and each plate needs to be loaded & adjusted—they need to line up perfectly with each other. The ink needs to be evenly distributed across the roller and should stay even as ink gets pulled off onto the plate—depending on the image, sometimes the plate pulls off more or less ink, and the press operator needs to compensate for this. The flow of water across the plate needs to be adjusted based on the press speed, balanced with the amount of ink on the sheet, and is also affected by temperature & humidity.

The best way to test a press during setup is to run paper through it and analyze the printed image—all offset presses use a little bit of paper at the beginning of every run that won’t be included with the finished job. Press operators call this waste makeready. Once the setup is complete, an offset press runs fast and with consistent accuracy.

Digital Printing

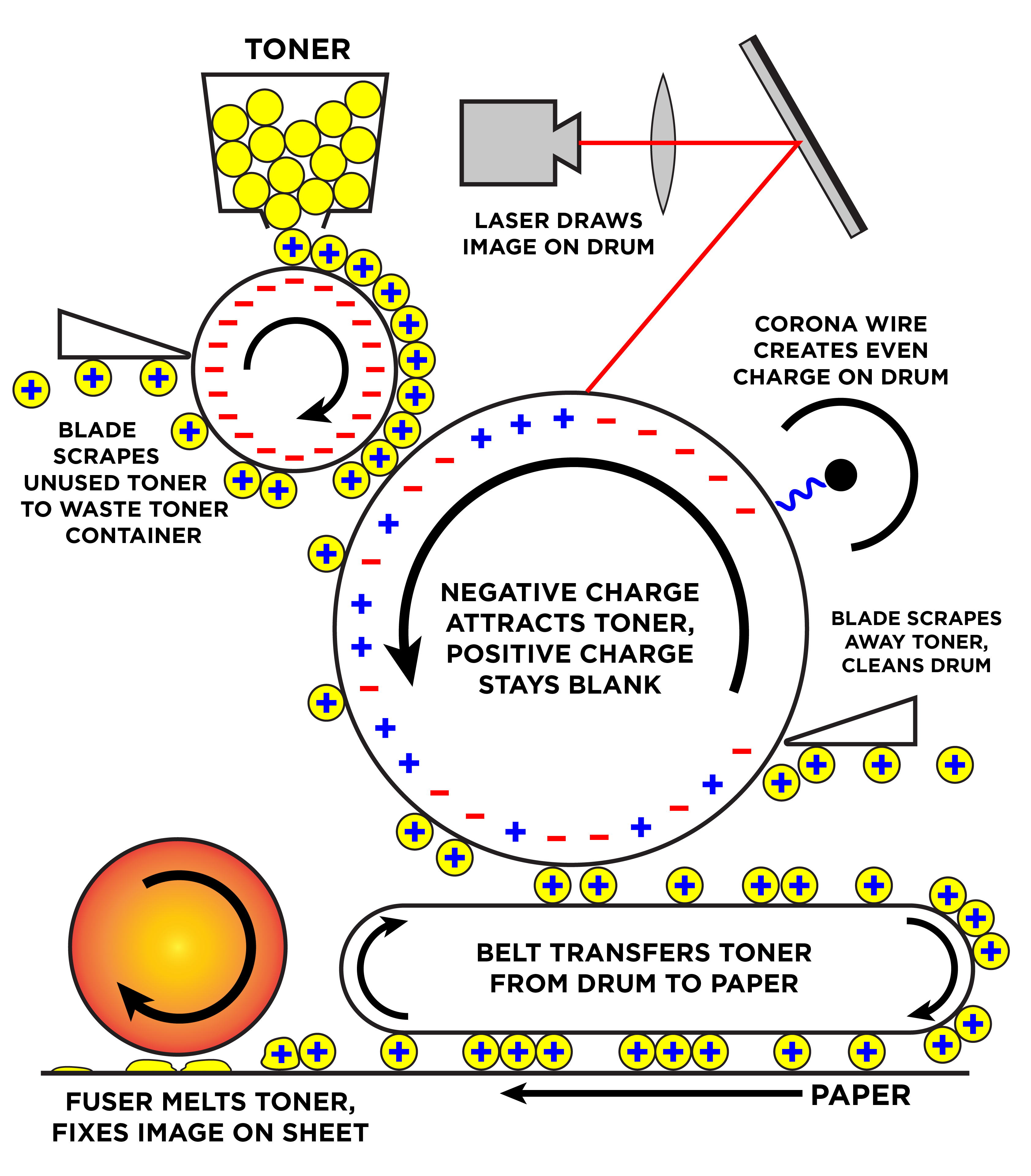

Digital printing usually refers to laser printing, which evolved out of xerography in the 1930s. Early Xerox machines bounced bright light off an original (which was usually pressed flat to a piece of glass) and projected the image onto a charged drum. Modern laser printers use a laser to draw the image directly onto the drum. The drum attracts electrostatically charged toner particles and transfers them to paper. The paper passes under a heated fuser roll to fix the image onto the surface.

Digital printing requires setup and adjustment, but much of it is computer-controlled and accomplished with minimal operator intervention. Sensors scan the image directly on the transfer belt and make adjustments wasting any paper. Since the machine is essentially wiping the drum clean and redrawing the image with each rotation, it can draw a different image on each sheet—a laser printer can print a multi-page document just as fast as multiple copies of the same document. Modern digital presses also include many self-checking features that periodically adjust for registration & color balance in the middle of a longer run.

Advantages & disadvantages to offset printing

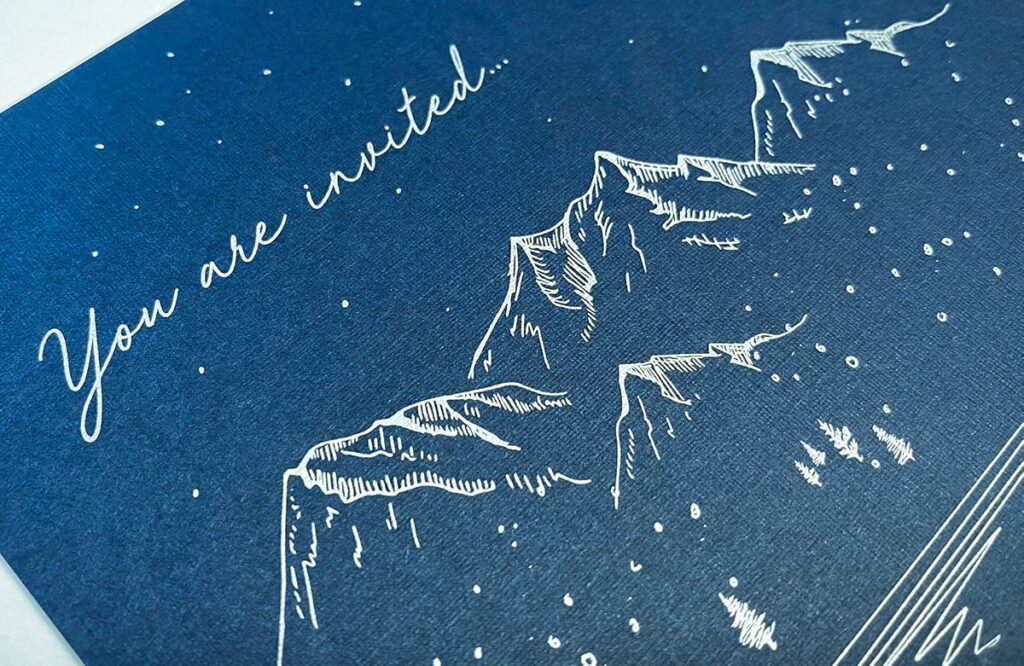

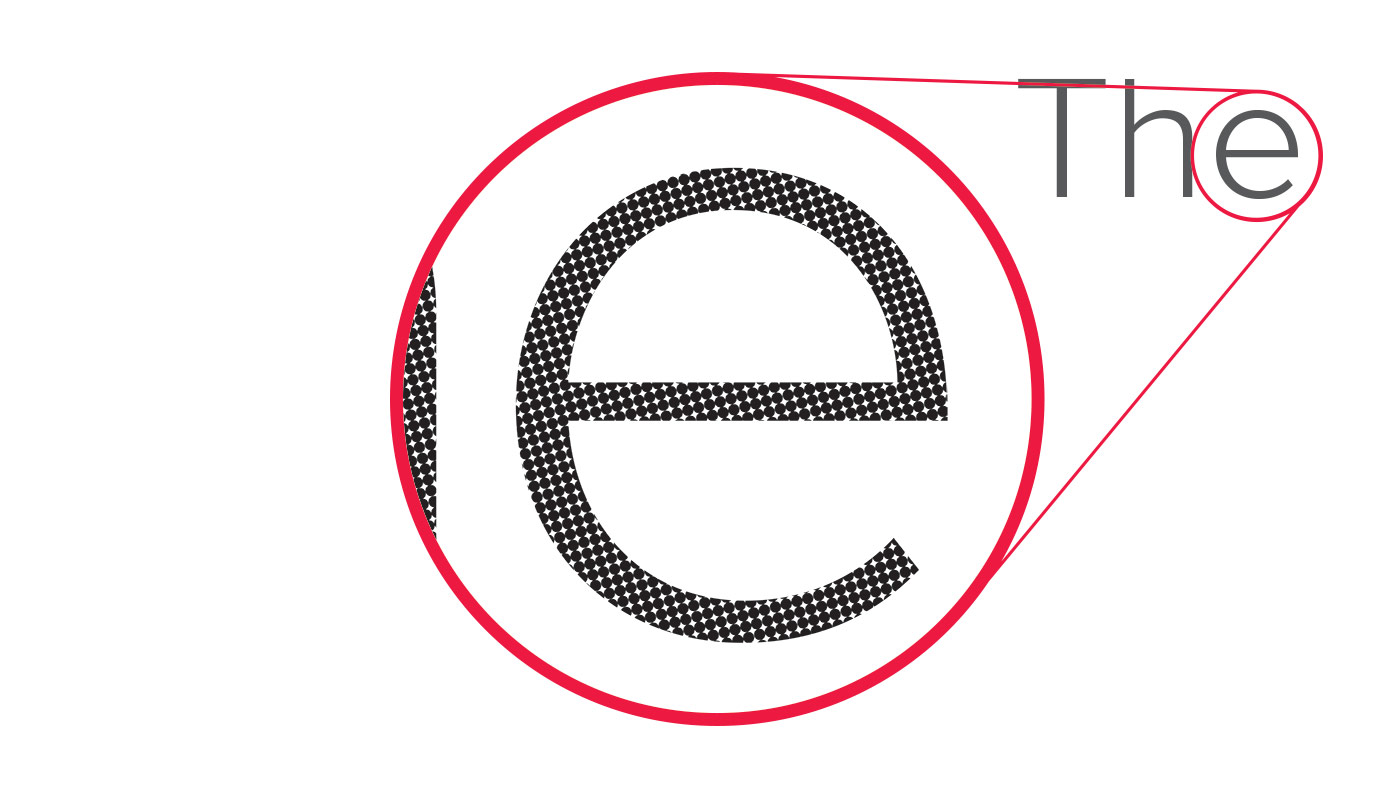

Offset printing is the industry standard for high quality. The consistency of an offset “dot” creates sharp images. Offset presses can easily print inks other than standard process color—it’s easy to clean off an ink roller and load a spot color, a metallic, or a fluorescent ink and achieve effects impossible to replicate with printer toner.

Plates and setup represent your “investment” in a print job: the initial cost is high, but once it’s done the press runs fast and economically. The “per sheet” price on an offset press can be a fraction of what it costs to print digitally if the quantity is high enough.

Proofing an offset job can be tricky—you can’t run a test page without the full amount of setup and makeready. Some printers supply color-calibrated laser or inkjet proofs, but these can’t replicate the quality of offset printing with 100% accuracy. The best way to proof an offset job is with a press check—if color is critical, the print buyer or graphic designer is physically present when the press starts rolling in order to inspect the first few sheets. Of course, if there are issues with the design, it could require making new plates and repeating the setup all over again.

Heavy ink coverage on a sheet can cause problems. Uneven buildup of ink on the rollers can lead to toning or scumming (ink transferring to the sheet where it’s not supposed to), ghosting (not enough ink left on the roller to deposit across the entire sheet), or offsetting (ink transferring to the unprinted side of the sheet on top). Sometimes special care has to be made as to how sheets are arranged on a press sheet, or in which order they’re printed. Drying time is also important for offset print jobs. If there isn’t enough time allowed before bindery (trimming, folding, etc.), it can lead to additional offsetting problems.

Advantages & disadvantages to digital printing

Digital printing is usually ideal for runs of 1000 or fewer, synthetic (non-paper) stocks, variable jobs, or runs with multiple versions. Toner is essentially baked onto the surface of the sheet—it doesn’t soak in like ink does—so it’s not subject to the same sort of heavy coverage issues. It comes out of the machine dry and won’t rub off onto other pieces of paper. Laser printing always has a degree of sheen from the toner—it will never be as flat as offset ink on uncoated stock.

The cost of maintaining a digital press is usually higher than maintaining an offset press of comparable size—high-end digital presses involve a lot of complicated electronics, they require specialized technicians to maintain, and digital presses consume replaceable parts more frequently than offset presses. Where offset requires expensive setup but can drop to pennies per sheet, digital printing incurs minimal setup costs but the “per sheet” cost remains relatively high.

Digital printing has some inherent flaws—imaging drums are subject to electric current fluctuations that can cause banding, uneven tones, or halos around edges. The “dot” on a digital printer is always a full dot (solid circle), and small details can look fuzzy because of this. Since the toner is on the surface, prolonged use can wear faster than offset print and the print may start to flake off (you might see this with business cards carried around in a wallet for a long time, or on the folded edge of brochures).

Special design considerations

The paper surface makes a difference with offset printing. A coated sheet—often referred to as “glossy”, “satin”, or “semi-gloss”—is paper that’s coated with a fine layer of polymer, clay, or other mineral. Coated stocks absorb less ink than uncoated sheets and colors tend to be brighter and more vibrant. Uncoated sheets soak up more ink—this leads to more muted, less saturated colors but also creates a flat finish that’s difficult to replicate with digital printing. Offset printing is great for textured stocks because the rubber blanket can press into the surface of the sheet better than a digital transfer belt.

Pay special attention to small type in 4-color print jobs—offset or digital—especially where type is “built” (not 100% black) or reversed (white type on a dark background). The smaller type gets, the more apparent any registration errors become—often resulting in type that looks “fuzzy” or appears to have a cyan, magenta, or yellow shadow. With digital printing, the complete “dot” creates edges that aren’t as sharp as with offset printing—this can also lead to a “fuzzy” appearance. For small type (especially when printed digitally), it’s usually better to print a thinner version of the typeface and use 100% black than a print a standard weight at 80% grey.

In Summary

In general, offset presses are best for higher quantities and digital presses are best for lower quantities. But that’s not always the case. Digital presses can achieve a higher ink density than offset presses and don’t require special layout considerations or drying time. Offset presses can achieve higher precision and a flatter finish.

If a digital press is like a car, think of an offset press like a locomotive. They’re large, complicated pieces of machinery that require pre-planning and special training (and experience) to run. They’re most economical when they can run for a long time without stopping. With a digital press, you can practically push a button and go. You don’t need a ton of pre-planning, and they can be operated by a high-schooler with some basic training (just because they can be, though, it doesn’t mean they should be. Just like a taxicab or a delivery vehicle, extra training & experience is necessary for commercial situations)—they’re ideal for short, quick jobs that might be a little bit different each time.

You wouldn’t try to load up a Prius with 20 tons of steel, and you don’t hop on a freight train to run across town for lunch. In much the same way, offset and digital are well suited to different types of jobs. Sometimes the quantity or budget necessitates one over the other, sometimes the design dictates which is best. Either way, Seattle Printworks can help navigate which will work best for your job.